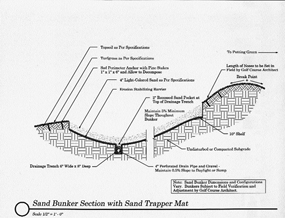

Bunker

construction will be augmented with erosion barrier and drainage added.

Each bunker will be shpaed to divert surface water and more strategically

placed.

Special

rootzone mix is being used on all greens to advance the quality of putting

to the highest levels on a year round basis. The practice facility was

built first to offer a 'finished product' to the membership during the

course shut down.

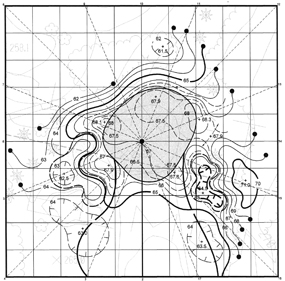

These

detailed drawings are somewhat emblematic of how Donald Ross used to detail

his greens. However, this method takes the detail to a much greater tolerance

because the speed of greens is critical to flagstick locations.

Belmont Country Club

After three years of planning, permitting and preparation the membership approval came with a majority vote to renovate and upgrade the entire golf course. Drainage, irrigation, tee and green construction, fairway contouring and golf car path improvements will all undergo major renovation. The facility will be modernized and improved to facilitate all types of players. Play conditions and quality will be the very best it can be.

This Donald Ross course was altered in the 70's to give way to an expansion of Rt. 2. Holes were lost and new ones designed to complete the 18-hole facility. Continuity was lost and lesser ground was used to build new holes. The end result was complicated by detrimental impacts from urbanization and flooding. The course will have a sophisticated drainage system that will eliminate constant wetness and all new putting greens with A4 creeping Bentgrass surfaces. The bunkering will all be new with erosion barriers to reduce erosion and increase playing consistency.

The complete renovation work will be done in a very short period of time. Irrigation and drainage work will be phased in such a way to work on non-play areas during the golf season. After Labor Day, the course will be closed and all work will be accelerated to finish before winter sets in.

The

overall master plan was developed to educated, inform and unify the membership

in the complete renovation of the golf course. The Committee did a masterful

job of communicating the necessity of the improvementgs and reducing the

impact of the implementation.

The

overall master plan was developed to educated, inform and unify the membership

in the complete renovation of the golf course. The Committee did a masterful

job of communicating the necessity of the improvementgs and reducing the

impact of the implementation.

Each original green will be rebuilt and restored to the original size. The slopes and angles will be deliberately engineered and graded meticulously to produce the optimal putting surface for each hole. With the use of A4 creeping Bentgrass, care must be taken to keep the surfaces of the greens in a range of slope that will insure adequate flagstick locations at high Stimpmeter readings. A detailed drawing of each green is made at 1" = 30' with a Layout Clock to insure that the size and grades along the perimeter are accurately transferred onto the site.

The existing outline of the original green is located on the detail to give the contractor a reference point and to orient the new putting surface in relation to the old green. The first green has the added benefit of being shaped to divert surface water away from the bunkers and to hide the golf car path located to the west.

The practice facility was built prior to the major work to allow golfers an optional place to practice while the main course is shut down for improvements.